Product Description

Slew Drive Mixer Epicyclic Sun and Planet Gear Motor Reducer Small Compound Wheel Drive Planetary Gearbox System Set Manufacturer

Application of Planetary Gearbox

Planetary gearboxes are used in a wide variety of applications, including:

- Machine tools: Planetary gearboxes are used in machine tools to provide power to the cutting tools. This allows for more precise cutting and helps to prevent the tools from becoming damaged.

- Conveyor belts: Planetary gearboxes are used in conveyor belts to transmit power from the motor to the belt. This ensures that the belt moves at a consistent speed and prevents it from becoming overloaded.

- Elevators: Planetary gearboxes are used in elevators to transmit power from the motor to the elevator car. This ensures that the car moves at a safe and comfortable speed.

- Wind turbines: Planetary gearboxes are used in wind turbines to convert the rotational energy of the turbine blades into electrical energy. This requires a high torque and low speed, which is what a planetary gearbox can provide.

- Other applications: Planetary gearboxes are also used in a variety of other applications, such as mixers, pumps, and printing presses.

Planetary gearboxes are typically classified by their size, speed, and power output. The size of a planetary gearbox is typically measured in diameter. The speed of a planetary gearbox is typically measured in revolutions per minute (rpm). The power output of a planetary gearbox is typically measured in horsepower (hp).

Planetary gearboxes can be either single-stage or multi-stage. Single-stage planetary gearboxes have 1 set of gears. Multi-stage planetary gearboxes have 2 or more sets of gears. Multi-stage planetary gearboxes can provide a wider range of speed reductions than single-stage planetary gearboxes.

Planetary gearboxes can be either open or enclosed. Open planetary gearboxes are exposed to the elements. Enclosed planetary gearboxes are protected from the elements. Enclosed planetary gearboxes are typically used in applications where there is a risk of contamination, such as in food processing plants.

Planetary gearboxes are a versatile and essential part of many machines and devices. They provide a number of benefits, including:

- High torque: Planetary gearboxes can provide a high amount of torque, which is essential for applications that require a lot of force, such as drilling and milling.

- Low speed: Planetary gearboxes can operate at very low speeds, which is essential for applications such as machine tools and wind turbines.

- Compact size: Planetary gearboxes are typically very compact, which makes them ideal for use in machines and devices where space is limited.

- Reliable operation: Planetary gearboxes are typically very reliable and have a long lifespan.

Overall, planetary gearboxes are a valuable tool for many industries. They can help to improve the efficiency, performance, and safety of a wide variety of machines and devices.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Steel |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

How does an epicyclic gear mechanism work in automatic transmissions?

An epicyclic gear mechanism, also known as a planetary gear system, plays a crucial role in the operation of automatic transmissions. Here’s a detailed explanation:

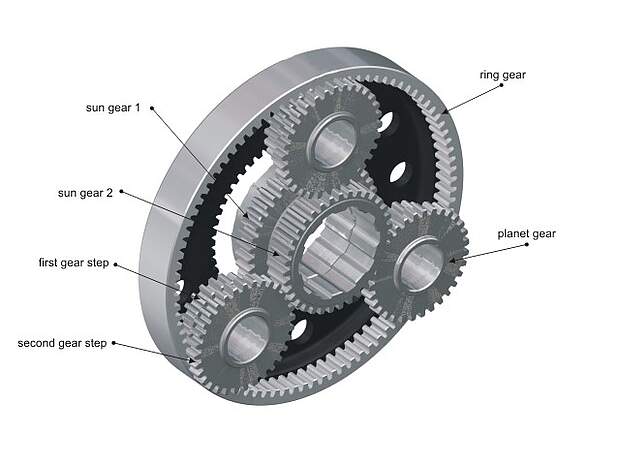

An automatic transmission utilizes a combination of different clutches, bands, and an epicyclic gear system to achieve gear ratios and control the transfer of power from the engine to the wheels. The epicyclic gear mechanism consists of the following components:

1. Sun Gear:

The sun gear is a central gear placed at the center of the mechanism. It receives power from the engine and is connected to the input shaft of the transmission.

2. Planet Gears:

Several planet gears are arranged around the sun gear and mesh with both the sun gear and the ring gear. The planet gears are mounted on a carrier, which allows them to rotate around the sun gear.

3. Ring Gear:

The ring gear is the outermost gear in the mechanism and has internal teeth that engage with the planet gears. The ring gear is connected to the output shaft, which transfers power to the wheels.

Here’s how the epicyclic gear mechanism works in an automatic transmission:

1. Neutral Position:

In the neutral position, no gears are engaged, and power flows freely through the transmission without any gear reduction or multiplication. The sun gear and the ring gear remain stationary.

2. Gear Engagement:

When a specific gear is selected, hydraulic clutches and bands are used to engage and disengage various elements of the epicyclic gear mechanism. The clutches and bands selectively hold and release specific gears to achieve the desired gear ratio.

3. Gear Ratios:

The gear ratio is determined by the arrangement and engagement of the gears in the epicyclic gear system. The sun gear, planet gears, and ring gear interact to produce different gear ratios. By selectively holding or releasing specific gears using clutches and bands, different gear ratios can be achieved, allowing the transmission to adapt to different driving conditions.

4. Power Flow:

The power flows through the different elements of the epicyclic gear mechanism based on the gear ratio selected. The input power from the engine is transmitted to the sun gear. Depending on the gear ratio, power is then transferred to the planet gears and the ring gear. The output shaft, connected to the ring gear, receives the power and transfers it to the wheels, propelling the vehicle.

5. Shifting Gears:

When shifting gears, the hydraulic control system of the transmission adjusts the engagement of the clutches and bands, causing the epicyclic gear mechanism to shift to a different gear ratio. This allows for seamless and automatic gear changes without the need for manual shifting.

Overall, the epicyclic gear mechanism in automatic transmissions enables the transmission to provide different gear ratios, control power flow, and facilitate smooth gear shifting. This mechanism plays a crucial role in the efficient and automatic operation of automatic transmissions in vehicles.

How do epicyclic gears maintain smooth operation during gear shifts?

Epicyclic gears, also known as planetary gears, are designed to maintain smooth operation during gear shifts. Here’s a detailed explanation:

1. Overlapping Engagement:

During gear shifts, epicyclic gears often utilize overlapping engagement, which means that multiple gears are engaged simultaneously for a brief period. This overlapping engagement allows for a gradual transition of torque from one gear to another, reducing sudden shocks or impacts that can cause jerky movements or noise.

2. Synchronizers or Clutches:

In certain applications, synchronizers or clutches are used in conjunction with epicyclic gears to facilitate smooth gear shifts. Synchronizers help match the speeds of the gears being engaged, while clutches enable gradual engagement and disengagement of gears. These mechanisms ensure that the gear shifts are seamless and minimize any jolts or vibrations.

3. Controlled Torque Transfer:

Epicyclic gears allow for controlled torque transfer during gear shifts. By manipulating the arrangement of the gears, such as holding a specific gear stationary, the torque can be gradually transferred from one gear to another. This controlled torque transfer helps maintain smooth operation during gear shifts.

4. Proper Gear Design:

The design of epicyclic gears plays a crucial role in maintaining smooth operation during gear shifts. Factors such as gear tooth profile, backlash, and clearance are carefully considered to minimize any sudden changes in contact and minimize gear meshing noise. Well-designed gears ensure smooth and efficient power transmission during gear shifts.

5. Lubrication and Damping:

Effective lubrication of the gear system helps reduce friction and wear during gear shifts. It also aids in damping vibrations and noise generated during the shifting process. Proper lubrication and damping techniques ensure smooth operation and minimize any disturbances during gear shifts.

6. Precise Manufacturing and Assembly:

Precision manufacturing and assembly of epicyclic gears are essential for maintaining smooth operation during gear shifts. Accurate gear tooth profiles, tight manufacturing tolerances, and precise gear alignment help ensure proper gear meshing and minimize any irregularities that can cause jolts or noise during gear shifts.

In summary, epicyclic gears maintain smooth operation during gear shifts through overlapping engagement, the use of synchronizers or clutches, controlled torque transfer, proper gear design, lubrication and damping techniques, as well as precise manufacturing and assembly. These factors work together to ensure seamless gear shifting, minimize shocks or impacts, and provide a smooth and comfortable driving experience in various applications.

What are the applications of epicyclic gears in various industries?

Epicyclic gears, also known as planetary gears, have a wide range of applications across various industries. Here’s a detailed explanation of their applications:

1. Automotive Industry:

Epicyclic gears are extensively used in automotive transmissions. They provide multiple gear ratios, allowing vehicles to efficiently transfer power from the engine to the wheels at different speeds. Automatic transmissions, dual-clutch transmissions, and continuously variable transmissions (CVT) often employ epicyclic gear systems to achieve smooth gear shifts, improved fuel efficiency, and enhanced performance.

2. Robotics and Automation:

Epicyclic gears play a crucial role in robotic systems and automation equipment. They are used in robotic joints and manipulators to control movements and transmit torque. The compact size, high torque capacity, and versatility of epicyclic gears make them ideal for precise and efficient motion control in robotics.

3. Aerospace Industry:

Epicyclic gears find applications in the aerospace industry, particularly in aircraft engines and auxiliary systems. They are used in gearboxes to transmit power from the engine to various components, such as generators, pumps, and auxiliary systems. Epicyclic gears are preferred for their compactness, high torque capacity, and ability to achieve multiple gear ratios.

4. Power Tools:

Epicyclic gears are widely employed in power tools such as drills, impact drivers, and wrenches. They provide the necessary torque multiplication and speed reduction to deliver high power output. Epicyclic gears enable power tools to efficiently transfer and control rotational motion, enhancing their performance and usability.

5. Industrial Machinery:

Epicyclic gears are used in various industrial machinery and equipment. They find applications in conveyors, printing machines, textile machinery, packaging equipment, and more. Epicyclic gears enable speed control, torque multiplication, and directional changes, facilitating the efficient operation of industrial processes.

6. Renewable Energy:

Epicyclic gears are utilized in wind turbines and solar tracking systems. They help optimize the rotational speed of wind turbine blades and enable solar panels to track the movement of the sun. Epicyclic gears contribute to efficient power generation in renewable energy systems.

7. Medical Devices:

Epicyclic gears have applications in medical devices and equipment such as surgical robots, imaging systems, and prosthetic devices. They enable precise and controlled movements, ensuring accurate diagnostics, surgical procedures, and rehabilitation.

These are just a few examples of the diverse applications of epicyclic gears. Their ability to provide multiple gear ratios, compactness, high torque capacity, and versatility make them indispensable in a wide range of industries where efficient power transmission and motion control are essential.

editor by CX 2023-10-08